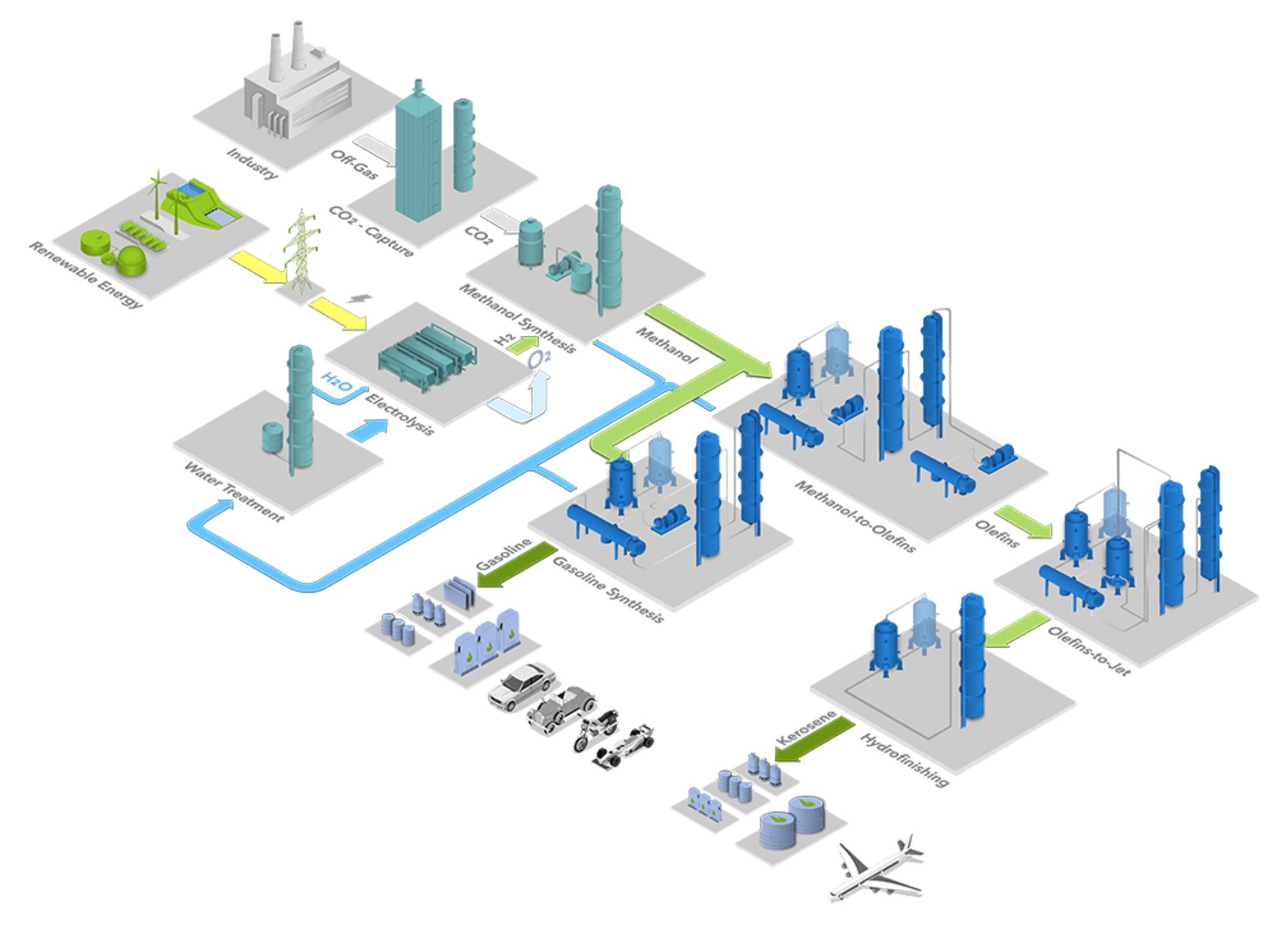

The manufacture of synthetic fuels such as gasoline and kerosene is undertaken using the in-house CAC "Methanol-to-Fuel" (MTF) and "Methanol-to-Jet fuel" (MTJ) technologies, in a power-to-liquid process chain from the initial components water, CO2 and renewable electricity – the latter, for example, from wind and hydropower, solar energy or biomass. The CO2 can be extracted from the air or (industrial) point sources.. The electricity is used in the electrolysis of water to generate hydrogen and oxygen. In the subsequent process stage CO2 and H2 are synthesised into methanol. The methanol created in this manner not only constitutes a key platform chemical for diverse follow-on applications, it is also the basic material for CAC’s fuel synthesis technologies and gives its name to this type of power-to-liquid process chain; the so-called methanol route.

CAC’s fuel syntheses enable the production of gasoline and kerosene via a single-stage or three-stage technology path. The main products meet standard specifications and the process plant economy is further enhanced through valuable by-products such as diesel (only with MTJ), LPG and fuel gas.

![[Translate to English:] [Translate to English:] Dr. Michael Haberland (Automobilclub Mobil in Deutschland), Dietmar Possart, Vorstand von Benzin-Kontor, Bundestagsabgeordneter Martin Huber und Philipp Arner, Geschäftsleiter Tankstellen bei der BK Benzin-Kontor AG betanken einen VW Käfer mit unserem E-Fuel.](/fileadmin/_processed_/4/e/csm_Haberland01_d8e992539d.jpg)