Our technology is sustainable

Synthetic Kersone. Produced with the CAC technology from three components: Electricity, Water, CO2. Completely without fossil fuels. Gained from renewable energies, the kerosene can be produced in a CO2-neutral manner.

To ensure Germany achieves net zero greenhouse gas emissions by 2045, our technology for synthetic kerosene from green hydrogencan make a significant contribution to the energy transition.

Jörg Engelmann

Chairman

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/_processed_/e/2/csm_CAC_Herr_Joerg_Engelmann_Buero_frontal_6b568b9882.jpg)

Our technology is revolutionary of its kind worldwide. Using methanol as an energy source, synthetic kerosene is generated, which can either be blended or used as a pure fuel.

Dr. Mario Kuschel

Head of Research & Development

The positive side effect of kerosene synthesis is the generation of gasoline and diesel as by-products. This means that in addition to the aviation sector, road transport also benefits from CO2-neutral fuels.

Dr. Rene Stahlschmidt

Head of Sales

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/1/c/csm_CAC-Herr-Dr-Stahlschmidt-47510_Vorschauen_quadrat_1b8c66766f.jpg)

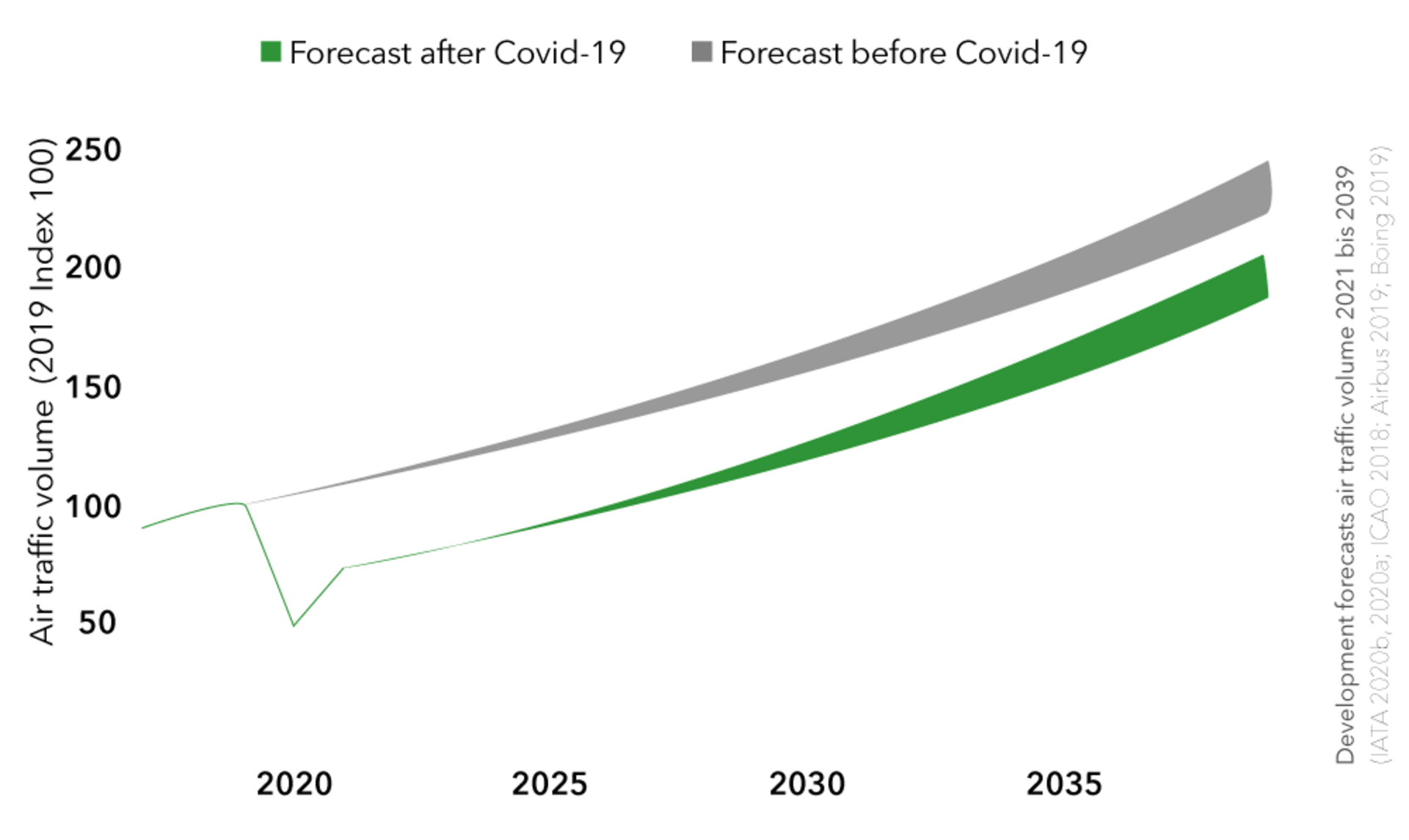

Increasing global mobility has led to a significant rise in cargo and passenger flights over the past decades. According to various development forecasts, this trend and the accompanying demand for kerosene are set to continue, regardless of numerous attempts at technical and operational optimisation.

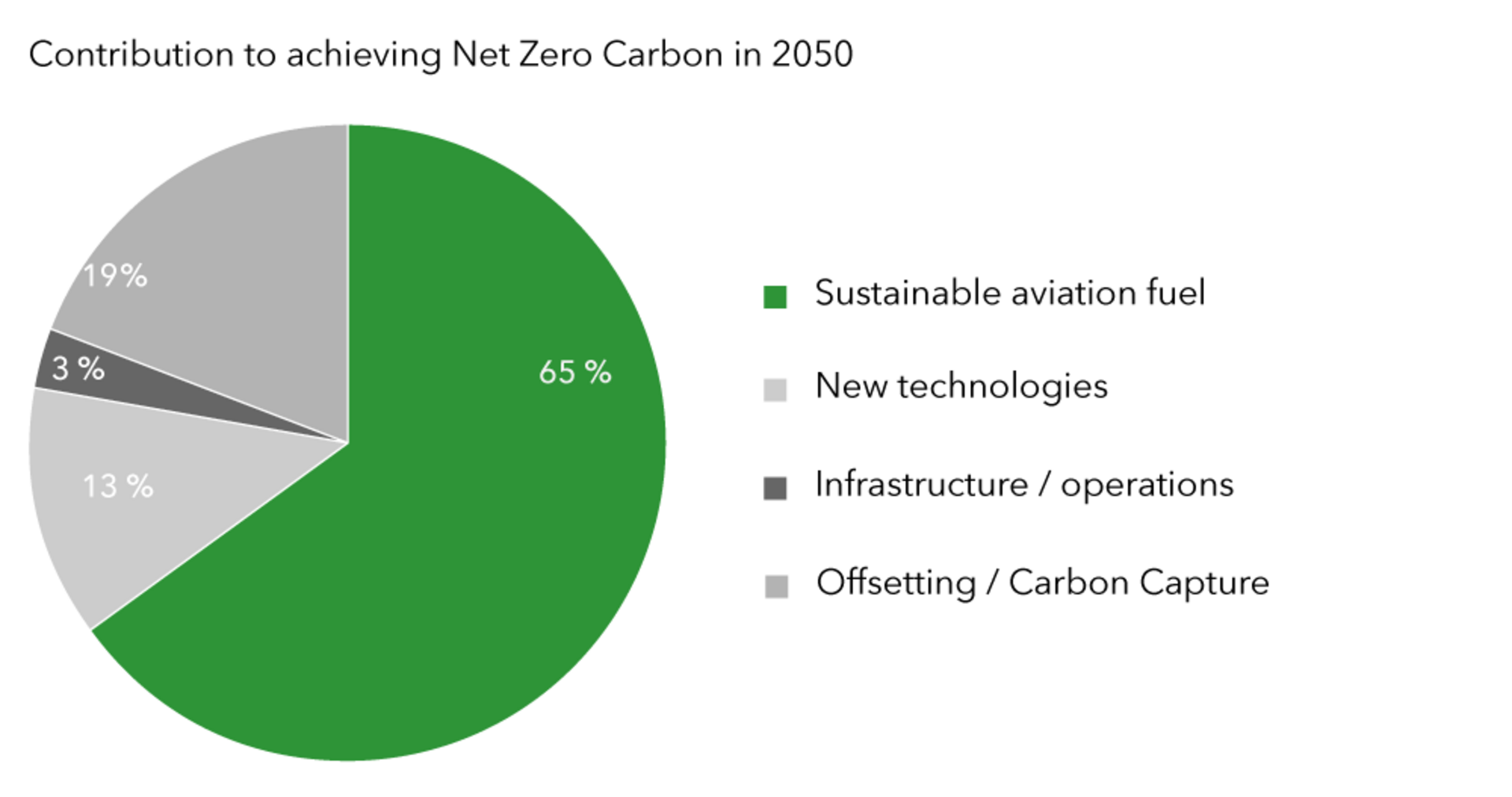

Sustainable aviation fuel (SAF) from renewable energy sources is the key to guiding aviation into a responsible, low-CO2 future. In this, the use of SAF helps to significantly reduce dependency on fossil aviation fuel. CO2, water and electricity are used to create methanol, which is transformed into sustainable kerosene using CAC’s Methanol-to-Jet fuel technology. In this way, the process enables the provision of SAF and contributes to fulfilment of the European Climate Law.

The first methanol-based kerosene plant worldwide – the goal of CAC with the KEROSyn100 R&D project. Together with partners from research and industry, CAC is working on the market launch of synthetically produced kerosene and planning a large-scale demonstration plant to be located at the refinery in Heide, Schleswig-Holstein. This new, methanol based SAF technology is sponsored by the Federal Ministry for Economic Affairs and Climate Action.

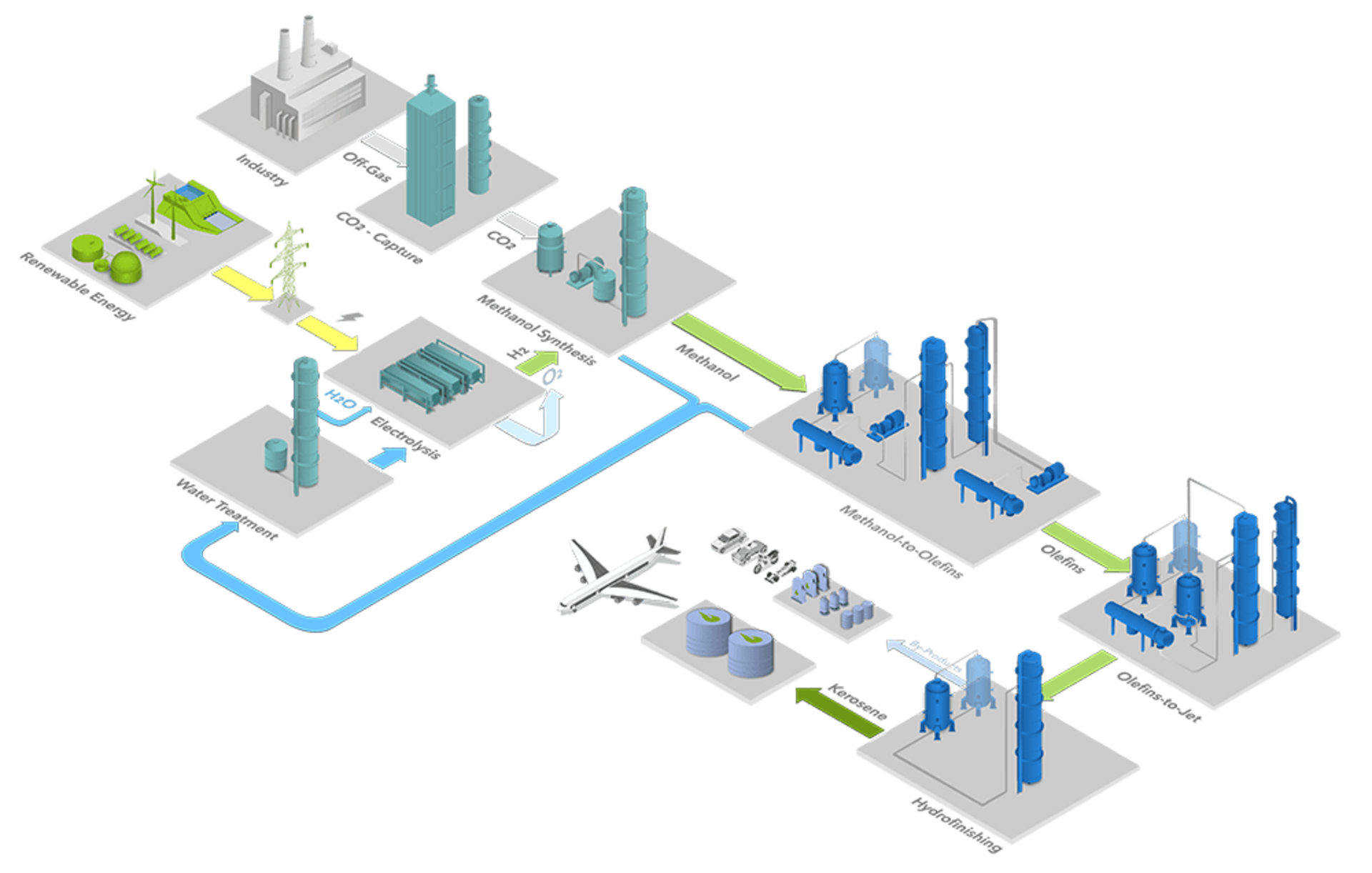

CAC’s Methanol-to-Jet fuel technology is subdivided into the process stages Methanol-to-Olefins (MtO), Olefins-to-Jet fuel (OtJ) and hydrofinishing. In addition to the primary product kerosene, by-products are also created: diesel, gasoline, LPG, fuel gas and water.

The fuel gas created by the reaction can also be used as an energy source in the plant itself. Process reaction water can also be separated and reused in the overall context of a power-to-liquid (PtL) plant complex in water electrolysis for the generation of hydrogen. This reduces the net water requirement in the PtL process.

Sustainable solution for air traffic

The manufacture of sustainable aviation fuel (SAF) begins with the provision of the source materials: CO2, water and “green” electricity. The latter is derived from renewable energies such as hydroelectric power, wind and solar energy. Water electrolysis separates the water molecule into oxygen (02) and hydrogen (H2). The subsequent manufacture of methanol – the source material for synthetic kerosene – from H2 requires additionalCO2, which is either acquired from the ambient air (Direct Air Capturing = DAC) or separated directly from industrial exhaust gases. This means that CO2does not enter the atmosphere but is incorporated directly into fuel production.