Our technology is sustainable

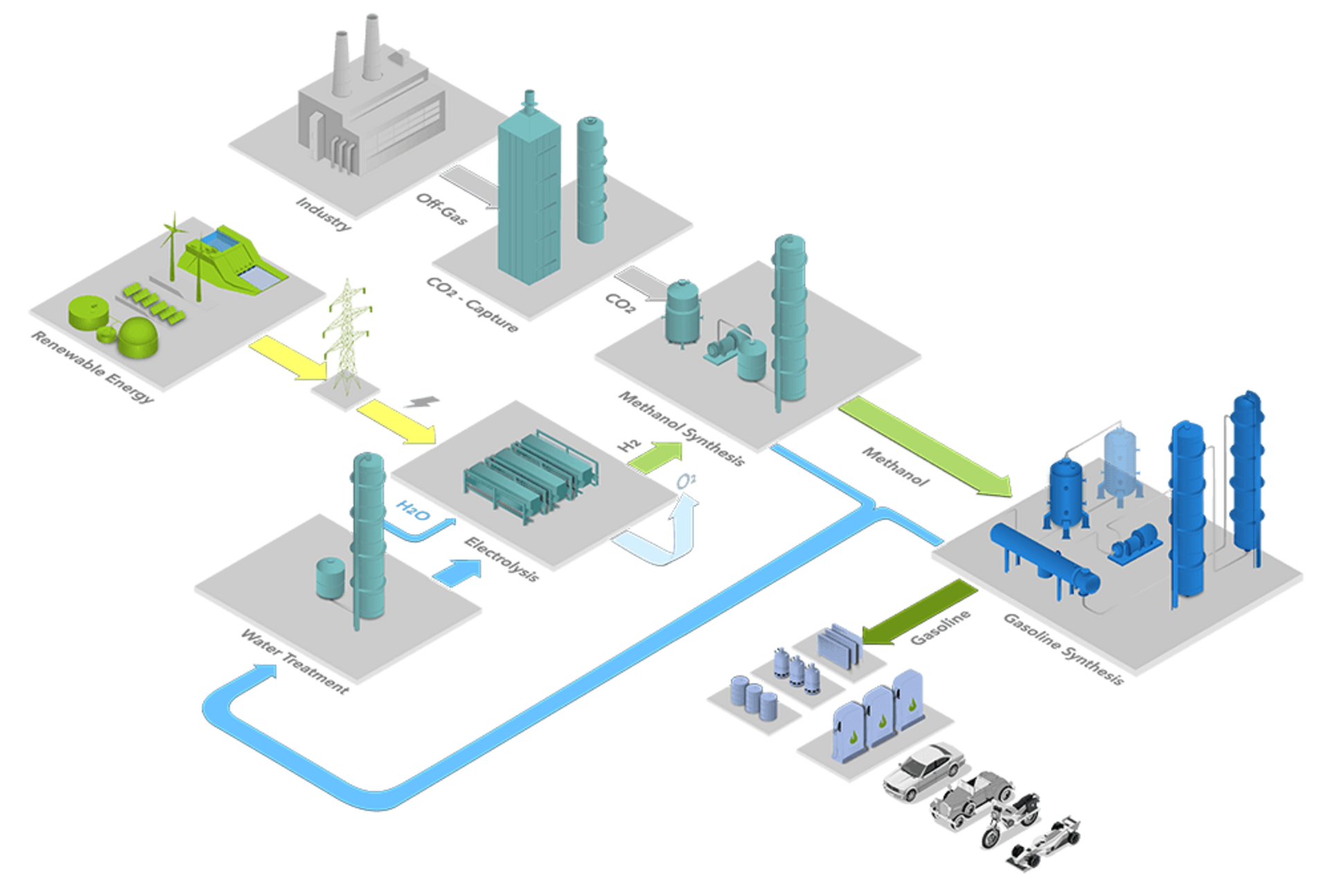

Synthetic Gasoline. Produced with the CAC technology from three components: Electricity, Water, CO2. Completely without fossil fuels. Gained from renewable energies, the kerosene can be produced in a CO2-neutral manner.

The solution is not the engine, but the fuel. International car and motorcycle manufacturers attest our REACH-certified synthetic gasoline has 100 per-cent compatibility with the existing vehicle fleet.

Jörg Engelmann

Chairman

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/_processed_/e/2/csm_CAC_Herr_Joerg_Engelmann_Buero_frontal_6b568b9882.jpg)

Climate protection calls for technological open-mindedness. In our process, gasoline can be manufactured in an almost CO2-neutral manner with CO2, water and electricity – ideally from renewable sources in energy-rich regions.

Dr. Mario Kuschel

Head of Research & Development

With our market-ready technology, e-fuels can be produced immediately on a large scale and used in any gasoline engine via the existing transport and filling station infrastructure - without the need for technical alterations to the vehicle.

Dr. Rene Stahlschmidt

Head of Sales

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/1/c/csm_CAC-Herr-Dr-Stahlschmidt-47510_Vorschauen_quadrat_1b8c66766f.jpg)

The synthetic fuel ENVIRONMENTALLY-FRIENDLY, INEXHAUSTIBLE AND CO2-NEUTRAL:

Practical test confirms quality: The most important process stage in the manufacturing chain is the transformation of the methanol extracted from carbon dioxide and hydrogen into gasoline. In the demonstration plant at TU Bergakademie Freiberg, CAC has already produced more than 45,000 litres of the green gasoline. Provided to car manufacturers for fleet trials, the practical application of the fuel has been confirmed. Both the quality of the gasoline and the technical plant design enable realisation on a large industrial scale, thereby implementing the sustainability goals of the German government (RED II) with immediate effect.

REACH certified: As E10 blend, the drop-in-capable synthetic gasoline fulfils all requirements of DIN EN 228, it is registered according to REACH and can replace conventional fossil fuel directly or be blended with it – without the need for technical alterations to the vehicle.

Raw material

Electricity-based fuels - also known as e-fuels - are liquid, synthetic fuels. They are produced from electricity, hydrogen and carbon dioxide.

Technology

- Over 45,000 litres produced

- Provided to car manufacturers

- Practical suitability confirmed

Application

The gasoline produced using the CAC technology meets the European fuel standard DIN EN 228, has been tested successfully by the car industry and can be used as pure drop in fuel in existing tank and engine systems. In a further practise test, a BMW Mini completed the E-Fuels Infotour: the Mini completed 3,000 km in 12 days with our synthetic gasoline. After numerous stops throughout Germany, the tour also visited the large-scale test plant at TU Bergakademie Freiberg, where the synthetic gasoline for the Mini was produced. Following its great success, the E-Fuels Infotour is continuing in 2022.

More about the E-Fuels Infotour -here

Sustainable driving without the need for conversion

The manufacture of gasoline using the power-to-liquid process chain lays a marker for climate-friendly transport of the future. The use of CO2 as raw material makes it a resource that can be recycled with concepts of this kind, without the accumulation of additional new CO2 in the atmosphere. Gasoline produced in this way can continue to be used with the existing infrastructure, with no need for motorists to alter their usage habits.